Our Sevices

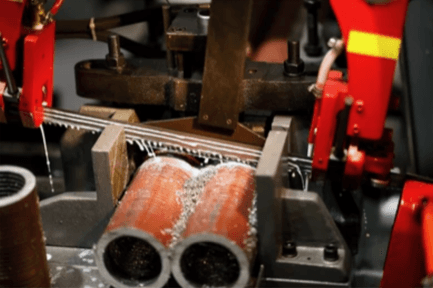

Sawing

Sawing machines are used cut a wide range of materials, including metals, plastics, and wood. They are often used in conjunction with other cutting processes, such as milling and drilling, to produce precision parts with a high degree of accuracy and repeatability.

Milling & Drilling

Milling involves the use of a rotating cutting tool to remove material from a workpiece, while drilling involves the use of a drill bit to create holes in the workpiece.

Welding

Welding is a fabrication process that involves the use of heat and pressure to join two or more metal pieces together. The process involves melting the metal at the joint, and then using a filler material to create a strong, permanent bond between the two pieces.

Heavy Brazing

Unlike welding, which involves melting the metal at the joint to create a fusion bond, brazing uses a filler material that is heated to a liquid state and then allowed to cool and solidify, creating a mechanical bond between the two parts.

Fabricating

Fabricating is a manufacturing process that involves the creation of metal structures and components through a variety of cutting, bending, and assembly techniques. It is a critical part of the manufacturing industry, and is used to produce a wide range of products, from small, intricate components to large, complex structures.

Fixtures & Tooling

Fixtures and tooling are specialized tools and devices used in manufacturing to hold, support, and manipulate workpieces during various machining and assembly processes. They are an essential part of the manufacturing process, and are used to ensure the accuracy, repeatability, and quality of the finished product.

Heat Treating

Metal heat treating is a process that involves the use of heat to alter the physical and mechanical properties of a metal. It is a critical part of the manufacturing process, and is used to improve the performance, durability, and longevity of metal parts and components.

Sand Blasting

Sand blasting is a process that involves the use of high-pressure air or water to forcefully spray abrasive particles against a surface, often with the aim of removing contaminants or coatings from the surface. It is a common manufacturing process, and is used to clean, prepare, and finish a wide range of materials, including metal, plastic, and glass.

Epoxy Coating & Painting

Epoxy coating and painting are processes used to protect and finish metal and other surfaces. Epoxy coatings are durable, long-lasting coatings that can provide excellent protection against corrosion, abrasion, and other forms of wear and tear.

Silver & Tin Plating

Silver and tin plating are processes used to apply a thin layer of silver or tin to a surface. These plating processes are often used to improve the appearance, conductivity, and corrosion resistance of the surface.